The development history of "DTF film"

DTF in the field of digital printing: Direct to Film

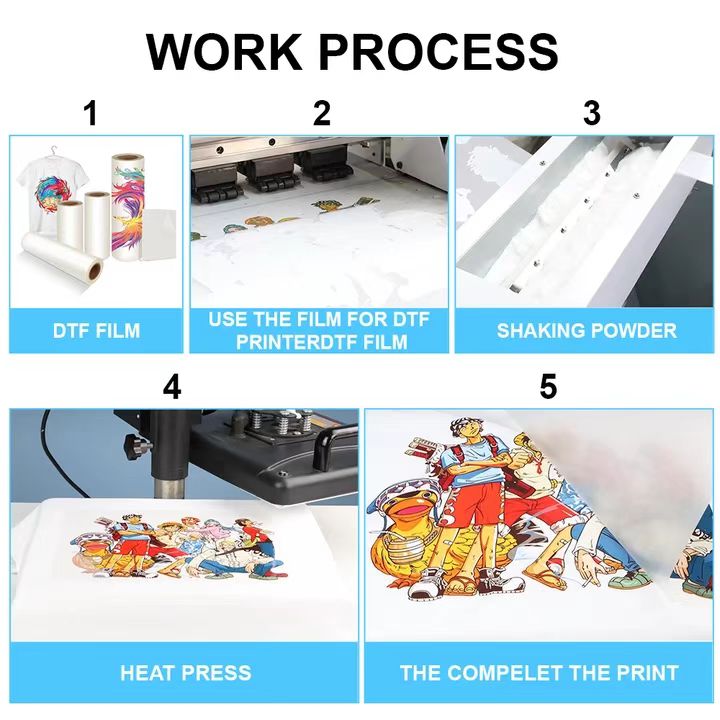

This is a heat transfer technology that involves printing patterns on a specially designed film and then heat-pressing and transferring them onto the surface of materials such as clothing. Its core driving force for development is the popularization of digital inkjet technology and the demand for personalized and fast-response production.

💡 technical advantages and influences

· Simplified process: Compared with traditional screen printing (requiring plate making) or heat transfer engraving film (requiring engraving and waste removal), DTF only needs three steps: "printing - powder coating - heat pressing", making the process simpler and more suitable for small-batch customization.

· Breaking through limitations: Its key technology lies in the application of white ink, which enables it to achieve bright and full-coverage patterns on dark-colored clothing.

· Cost reduction: The equipment investment and operation threshold are relatively low, making it easier for small and medium-sized printing enterprises and individual entrepreneurs to enter the market.

· Enhance efficiency: The on-demand printing model (production after customer orders) significantly reduces inventory costs and capital occupation, making it particularly suitable for e-commerce models.